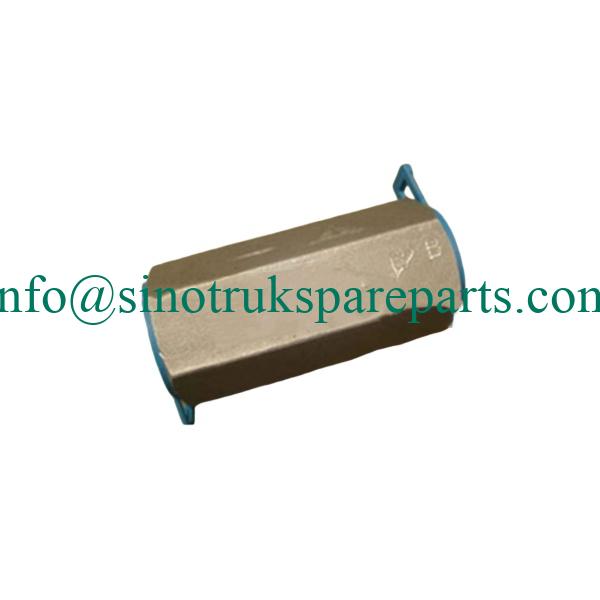

Le WG9000360507 Check Valve is a cornerstone of the Sinotruk howo parts ecosystem, designed to safeguard your vehicle’s pneumatic circuits against dangerous backflow.

Whether you are operating a HOWO 371 or a newer T7H model, this check valve (also known as a non-return valve) ensures that compressed air moves in a single direction—maintaining the pressure required for consistent braking and air suspension performance. Manufactured from high-strength alloy and fitted with heat-resistant internal seals, the WG9000360507 is built to withstand the carbon buildup and oil vapor common in high-mileage heavy trucks.

Spécifications techniques:

-

Nom de la pièce: Check Valve / Non-Return Valve

-

Numéro d'article: WG9000360507

-

Series Compatibility: Sinotruk HOWO, Steyr, Golden Prince

-

Body Material: Corrosion-resistant Die-cast Aluminum/Zinc Alloy

-

Nominal Pressure: 10.0 bar (Standard heavy-duty operating range)

-

Opening Pressure: ≤ 0.05 bar (Highly sensitive for rapid response)

-

Port Sizes: M22 x 1.5 (Standard metric threading for HOWO air lines)

-

Operating Temperature Range: -45°C to +110°C

1. NOUS TRAITONS CHAQUE CLIENT COMME NOTRE AMI, ADHÉREZ AU PRINCIPE: AVANTAGE GAGNANT ET MUTUEL ;

2. UNE VARIÉTÉ DE CHOIX DE PRODUITS: QUALITÉ, MARQUE, EMBALLAGE;

3. NOUS VOUS RÉPONDRE À VOTRE DEMANDE EN 24 HEURES.

4.Fournisseur de pièces SINOTRUCK de performance professionnelle

5. NOUS SERONS EN SERVICE 24/24 HEURES DE LA JOURNÉE DE TRAVAIL.

6. CUL: NOUS VOUS OFFRIRONS LE MEILLEUR SERVICE APRÈS-VENTE.

To maintain the long-term reliability of your Sinotruk howo parts, our engineering team recommends the following when replacing the WG9000360507:

-

Directional Flow Awareness: Look for the cast-in arrow on the valve body. This indicates the direction of airflow. Installing it in reverse will completely block the air supply to the tanks, leading to brake failure.

-

Clean the Lines: Before threading in the new valve, inspect the air lines for carbon deposits or moisture. A clogged line can cause the internal spring of the new valve to stick prematurely.

-

Avoid Over-Taping: While thread sealant or PTFE tape is recommended, do not apply it to the first two threads. Excess tape can break off, enter the pneumatic system, and clog downstream valves.

-

Leak Testing: Once installed, charge the system to full pressure and perform a "soap bubble test" on the joints. Even a microscopic leak can cause the air compressor to overwork, leading to premature failure of other Sinotruk howo parts.

-

Torque Settings: Use a calibrated wrench to tighten to 35-45 Nm. Excessive torque may crack the alloy housing.