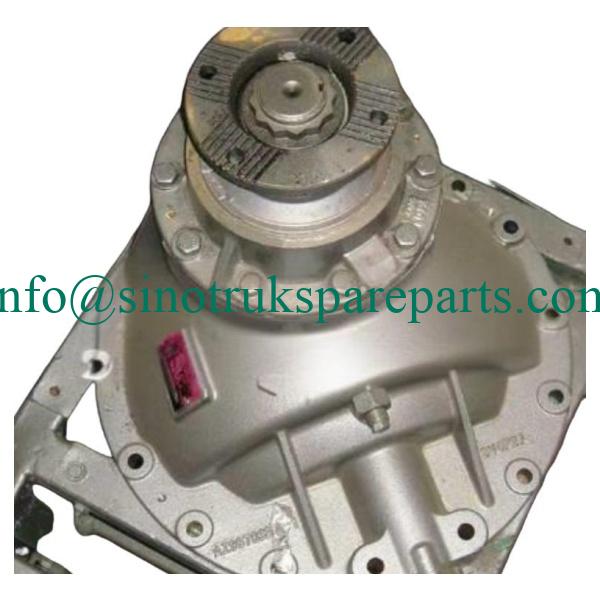

El WG9981340034 Brake Chamber Bracket is specifically designed for the right side of the rear axle on Sinotruk HOWO series trucks. Its primary function is to provide a rigid, vibration-free mounting platform for the air brake chamber, ensuring that braking force is applied consistently and without mechanical deflection.

Especificaciones técnicas

| Número de pieza OEM |

WG9981340034 |

| Solicitud |

Sinotruk HOWO, Howo T7H, HOWO TX |

| Position |

Rear Axle, Right Hand Side (RHS) |

| Material |

Heavy-Duty Reinforced Forged Steel |

| Tratamiento superficial |

Anti-corrosive Industrial Coating |

| Compatibilidad |

Standard Air Brake Systems |

1. TRATAMOS A CADA CLIENTE COMO NUESTRO AMIGO, PEGARSE AL PRINCIPIO: BENEFICIO MUTUO Y GANADOR ;

2. UNA VARIEDAD DE ELECCIÓN DE PRODUCTOS: CALIDAD, MARCA, EMBALAJE;

3. LE RESPONDEREMOS SU CONSULTA EN 24 HORAS.

4.Proveedor de piezas de rendimiento profesional SINOTRUCK

5. ESTAREMOS EN SERVICIO 24/24 HORAS DEL DÍA LABORAL.

6. CULO: LE OFRECEMOS EL MEJOR SERVICIO POSTVENTA.

Replacing a brake chamber bracket is a critical task. For fleet uptime and safety, we recommend following these professional steps:

-

Preparación: Secure the vehicle on a level surface. Release the spring brakes (manually if necessary) and support the axle with jack stands.

-

Eliminación: Disconnect the air lines from the brake chamber and remove the chamber from the old bracket. Inspect the bolts connecting the bracket to the axle housing—these often require a high-torque impact wrench due to road grime and rust.

-

Clean and Inspect: Once the old bracket is removed, clean the mounting surface on the axle housing. Check for any hairline cracks in the axle flange itself.

-

Fitment: Align the WG9981340034 soporte. It should seat flush against the mounting surface without forced prying.

-

Especificaciones de par: Use new high-strength bolts (Calificación 10.9). Tighten to the manufacturer-specified torque (refer to your HOWO service manual) to prevent loosening from road vibration.

-

Reassembly: Re-mount the brake chamber and reconnect the air lines. Perform a leak test and verify that the pushrod moves freely within the bracket’s clearance.